Food Container Mould ↗

Most of thin wall moulds are for food container mould. Food container is the biggest application for the thin wall mould. Short cycle time, long mould life… Read more…

Other Thin Wall Mould ↗

There are many other thin wall plastic products mould. Like thin wall nail, basin, other type of thin wall containers, etc. Find more information…

Thin wall mould is Taizhou Xiongshi Plastic Mould Co., Ltd main range products. We have more than 10 years experience in making thin wall products moulds. With such long experience, the thin wall moulds from us are all high quality and very long life.

Out factory Taizhou Xiongshi Plastic Mould Co., Ltd is a great plastic moulds factory located in “China Mold Town” – Taizhou City, China. We provide clients not only mould, but unforgetable good service, fast response on clients’ requirement. We win excellent reputations during our clients. Our moulds 90% for export, therefore we understand most countris clients’ request. And the processes of export moulds are deeply impressed in our brain.

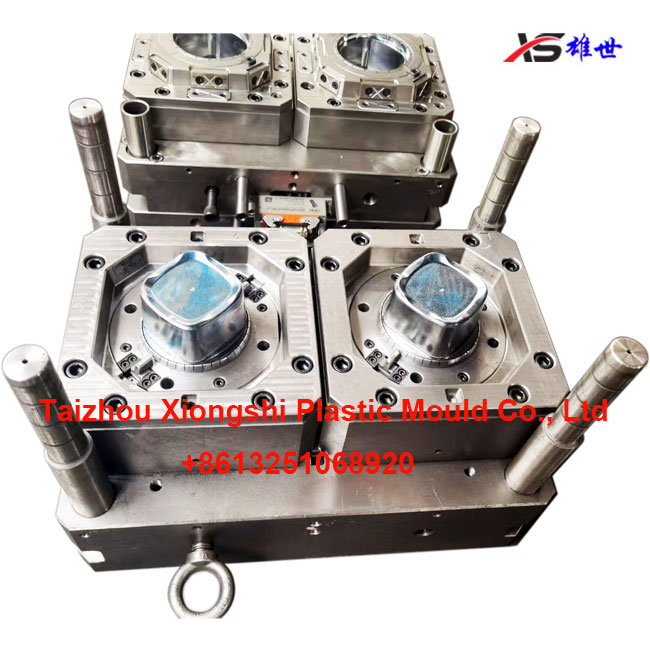

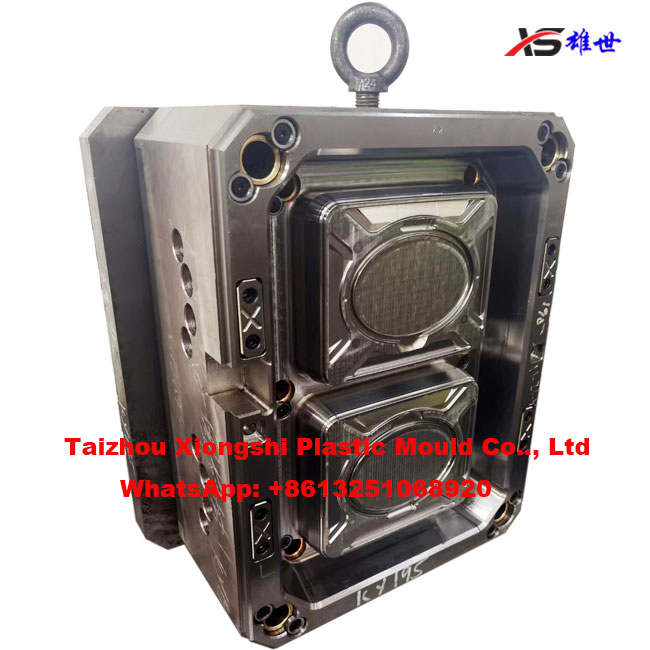

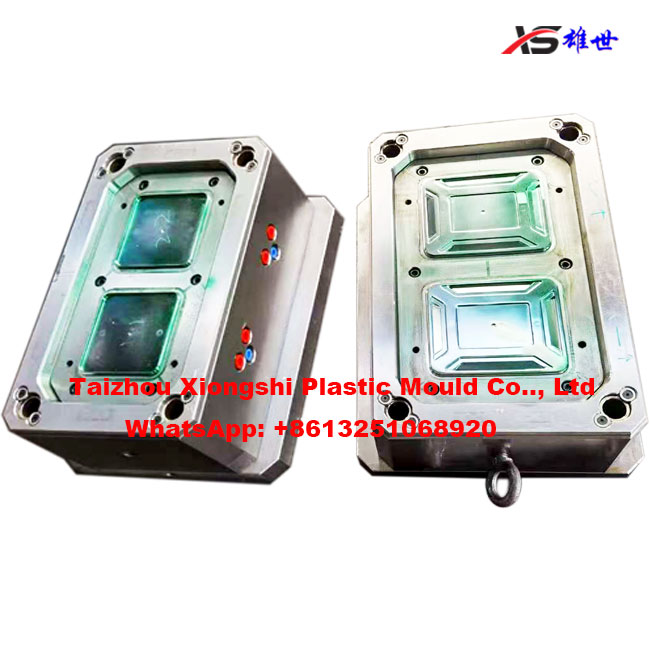

High quality mould need a good-looking appearance to tell people that is a good quality mould. Like a woman need to put on makeup to make herself more beautiful, one set mould also need trim to make it with excellent good-looking profile. Meanwhile the inner quality of our thin wall mould is same as its beautiful profile, it is made with high quality. The mould same outside and inside can be called good quality mould.

Normally thin wall products production quantity is very huge. So need mould with very long life, such as 1 million shots, 2 million shots or even 3 million shots. To make the mould with long life, the mould steel has to use expensive and high-quality steel. We usually use H13, H11, 1.2344, etc. to make the thin wall mould. The mould steel can be customized according to client’s request. In case steel after vacuum hardening treatment with hardness 48HRC-52HRC is not high enough, the mould will be done with nitriding treatment to make the steel hardness up to 60HRC.

Due to huge mass production, thin wall mould injection moulding need with short cycle time. Compare with cold runner system, hot runner can provide mould with shorter cycle time. So all the thin wall moulds manufactured with hot runner system. Include hot runner point gate and hot runner valve gate. What’s the different between them? Hot runner point gate, there is no pin inside of it, so nozzle without sealing function. But hot runner valve gate, there a pin inside of the nozzle, which can seal the nozzle on the end of the injection. So prolonged flow and wire drawing is not a problem for valve gate. But for point gate, these two problem is a challenge for injection molding technician. They need rich experience then properly can adjust the injection molding without these two problems. Anyhow, client can choose hot runner point gates for thin-wall mould, the reason is valve gate hot runner cost is too high. Taizhou Xiongshi Plastic Mould Co., Ltd will take mould test video and mould test injection machine setting parameter, and show them to client. This will be great helpfull for clients on injection molding.

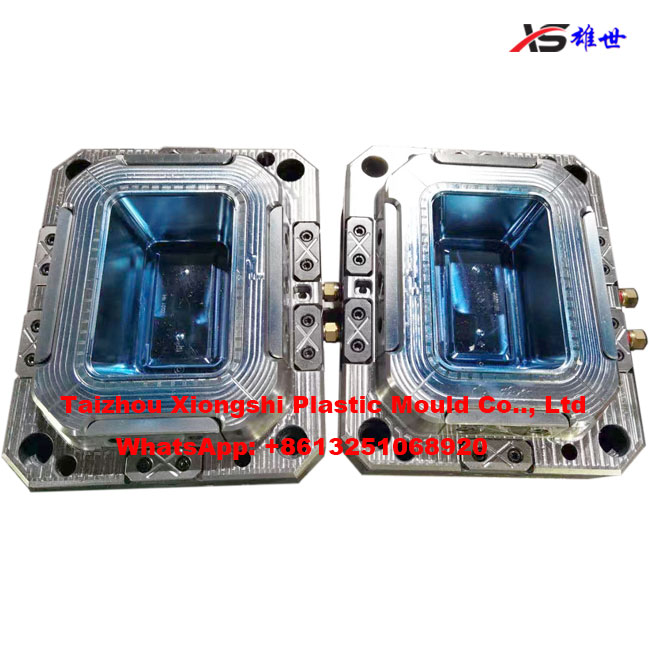

Thin wall mould cavity and core are inserts design. And it is best to design each cavity individually. The reason for this design, the first thing, each cavity core and cavity can clamp each other separately. This way provide much better clamping during injection moulding. And if found there is problem on this during the mould test, we can just modify the one which have problem, no need to change on whole mould. Another advantage for individual cavity block and core block insert design is when find wall thickness is uneven on the mould test samples, we can simplely improve this problem on the mould. While this change is very difficult job if mould all cavity made in one whole plate and all core made in one whole plate.

? CMM for thin wall mould

After mould finished the tooling and polish, we will make the CMM inspection for thin wall mould. This could help us to check and understand if there is tooling mistake on the mould. Especially for the wall thickness only 0.4mm, the uneven wall thickness is worse problem to run this mould on high speed injection machine. So we need to get know all the sizes details distributed on the mould.

? Thin wall mould picture show

Welcome to contact us to develop new thin wall mould.